Hollow Sucker Rod Electric Heating Device for Heavy Viscosity Oil

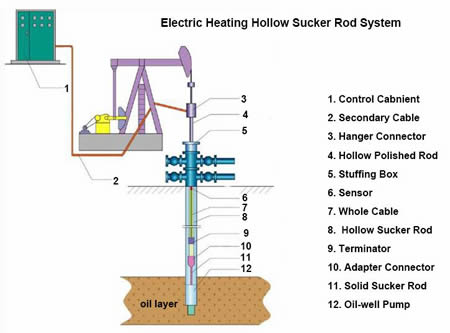

Sketch map of hollow sucker rod electric heating device.

Introduction

In the high viscosity, pour point and wax content situations, the crude oil has the difficult of lifting and flowing into the pump, the sucker rod bears too heavy load to downstream. So, the common sucker rod cannot play a good performance in the late of oil exploitation. There is a new device which can solve these problems - hollow sucker rod electric heating device.

Device structure

The hollow rod electric heating device is main combine with three parts.

- Hollow sucker rod. Including the adapter connector, terminator, pony rod, polished rod, hanger connector and stuffing box.

- Heating cable.

- Power unit. Medium frequency power supply control cabinet.

Classification

The hollow sucker rod electric heating device can be divided into pumping unit well electric heating device, subsurface pump hollow sucker rod electric heating device and screw pump hollow sucker rod electric heating device.

Pump unit hollow sucker rod electric heating device

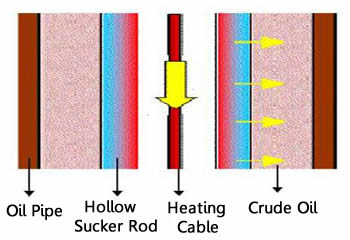

Sketch map of the skin effect.

Operating principle

Cables pass through the hollow sucker rod and form a loop with the rod body. When the alternating current is connected, it will generate thermal energy through the internal skin effect. The thermal energy will heat continuously crude oil in the oil pipe. It can reduce the viscosity of the crude oil, prevent wax precipitation in the oil pipe and improve the fluidity of crude oil. Using this device can solve the problems in exploitation, it can also increase the production and improve the efficiency.

The thermal energy generated by the internal skin effect is merely exist in the inner wall of the hollow sucker rod, the outer wall has no electric, and it can ensure the safety of operating.

Technical data

Hollow sucker rod

| Rod Outer Diameter | 34mm | 36mm | 42mm |

|---|---|---|---|

| Rod Thickness | 5.0mm, 5.5mm | 5.5mm, 6.0mm, 6.5mm | 6.0mm |

| Coupling Outer Diameter | 50mm | 50mm | 60mm |

| Thread Size | 1-9/16" | 1-9/16" | 1-7/8" |

| Grade | D | ||

Heating cable

| Heating core sectional area mm2 | 3 × 8.4mm2 |

|---|---|

| Outer diameter of cable | 18 - 20mm |

| Outer protect layer | Stainless steel wire armor weave |

| Withstand voltage | ≥ 2500V |

| Length | Underground length + ground length |

| Temperature-resist grade | Long time working temperature: 200°C (C Grade) |

| Electrical performance | Insulation resistance > 50MΩ, AC withstand voltage test 2500V |

| Tensile strength | ≥ 50Mpa |

Electric control cabinet

| Rated power KVA | 35 | 50 | 75 | 100 | 135 |

|---|---|---|---|---|---|

| Input voltage | Three phase 380V ± 5%, 50HZ, three phase 440V ± 5%, 60HZ | ||||

| Output voltage | Single phase160 - 900 is available. | ||||

| Power factor | COS Ø ≥ 0.95 | ||||

| Three phase imbalance percent | ≤ 10% | ||||

Subsurface pump hollow sucker rod electric heating device

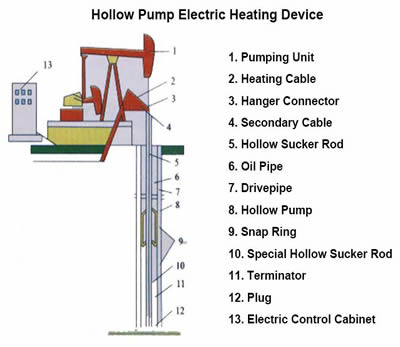

Sketch map of hollow pump electric heating device.

When the oil viscosity is between 100 to 10000mPa.s, hollow sucker rod electric heating device can be configured to a standard API mono barrel pump or special subsurface pump. It can heat the crude oil through the electric heating sucker rod to ensure the crude oil pumped into pump smoothly. But when the oil viscosity is more than 10000mPa.s, the crude oil is difficult to flowing into the pump, so we need use the electric heating sucker rod combined with electric subsurface pump to heat the crude oil above pump and under pump at the same time. This device can reduce the oil viscosity and solve the difficulty of flowing into the pump and wellbore lifting.

Device structure

The hollow sucker rod heat pump device is combined hollow sucker rod electric heating device with the electric heating subsurface pump.

Features

- This device can use the electric heating sucker rod to heat the crude oil in the tail pipe under pump directly. It can reduce the viscosity, increase the liquidity and improve pump admission coefficient.

- The traveling valve is open and closed forcibly to prevent airlock.

- Special hollow sucker rod under pump is also used as the weighted rod, which is in favor of plunger and improve the stress state of sucker rod.

- Reduce the viscosity in the electric heating way, which is ideal for the marginal area oil exploitation.

Screw pump electric heating device

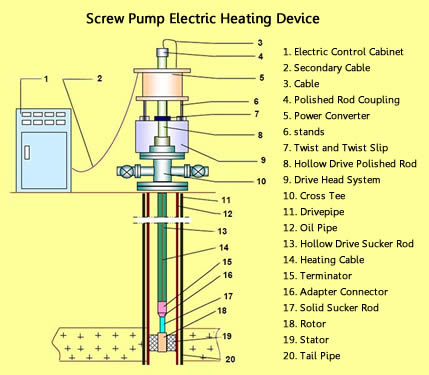

Sketch map of screw pump electric heating device.

Current situation

Movement in the screw pump is rotating motion. Bearing force mode of rod has been changed from tensile to torsional. The solid sucker rod is often generated fracture and trip. The driving hollow sucker rod for the screw pump can solve these problems, it has good performance of torsional resistance, fracture and trip resistance. Moreover, the driving hollow sucker rod can heat the crude oil in the whole production, so it is an important configuration of the screw pump electric heating device.

Device structure

The screw pump electric heating device is combined with electric control cabinet, power converter, heating cable and driving hollow sucker rod.

Operating principle

The screw pump electric heating device transform the stationary power on the ground to the transmission power rotating along the driving sucker rod. Pass through the cable through the hollow sucker rod to form a loop with sucker rod body. When the alternating current is power on, it will cause the inter skin effect, which can generate thermal energy on the rod wall. Just heat the crude oil in the whole production using the thermal energy to increase the temperature, reduce viscosity and improve liquidity of crude oil. It can also prevent oil from wax depositing, reduce the rotation torque and improve the performance of the whole device system.

Technical Data

Hollow sucker rod

| Rod Outer Diameter | 34mm | 36mm | 42mm |

|---|---|---|---|

| Rod Thickness | 5.0mm, 5.5mm | 5.5mm, 6.0mm, 6.5mm | 6.0mm |

| Coupling Outer Diameter | 50mm | 50mm | 60mm |

| Thread Size | 1-9/16" | 1-9/16" | 1-7/8" |

| Grade | D | ||

Heating cable

| Heating core sectional area mm2 | 3 × 8.4mm2 |

|---|---|

| Outer diameter of cable | 18 - 20mm |

| Outer protect layer | Stainless steel wire armor weave |

| Withstand voltage | ≥ 2500V |

| Length | Underground length + ground length |

| Temperature-resist grade | Long time working temperature: 200°C (C) |

| Electrical performance | Insulation resistance > 50MΩ, AC withstand voltage test 2500V |

| Tensile strength | ≥ 50Mpa |

Electric control cabinet

| Rated power KVA | 35 | 50 | 75 | 100 | 135 |

|---|---|---|---|---|---|

| Input voltage | Three phase 380V ± 5%, 50HZ, three phase 440V ± 5%, 60HZ | ||||

| Output voltage | Single phase160 - 900 is available. | ||||

| Power factor | COS Ø ≥ 0.95 | ||||

| Three phase imbalance percent | ≤ 10% | ||||

Sucker rod torsion test recommended value of torque

| Item | ETV-01 | ETV-02 | ETV-03 | ETV-04 | ETV-05 | ETV-06 |

|---|---|---|---|---|---|---|

| Specs | 22mm | 25mm | 28mm | 34mm × 5.5mm | 36mm × 6mm | 42mm × 6mm |

| Torgue value KN.m | ≥ 1.4 | ≥ 1.8 | ≥ 2.4 | ≥ 3.2 | ≥ 3.6 | ≥5 |

Features

- Drive hollow sucker rod for better resistance to the torsional.

- Heat the crude oil from rotor of the screw pump to the ground in the whole production, which can improve the heating efficiency and increase the liquidity of the crude oil.

- The heating temperature can be controlled, it can set the heating power according to the real situation.

- Easy to cooperate and manage.

- Improve the performance of whole device and improve the operating condition of the driving head motor system of the screw pump.

Inquiry for Our Product

LANTYTO® Machine

E-mail:

landy.industry21@gmail.com

When you contact us, please provide your detail requirements.

That will help us give you a valid quotation.