Sinker Bar

Introduction

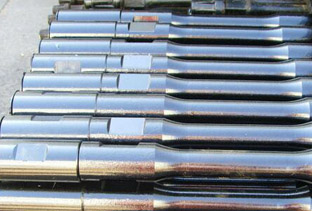

Sinker bars provide concentrated weight above the pump to help keep the rod string straight and in tension, which reduces buckling of the sucker rods or the pump plunger.Sinker bars are made from hot rolled carbon manganese steel bar stock. Sinker bars are surface turned and have API double sucker rod pins, shoulders, and wrench flats on both ends. One end has a reduced section for elevator seating and lifting.

Products Details

Sinker Bar is heavier than the conventional rod. It is used at the bottom of the sucker rod string to keep the rod string under tension and reduce crooks of the sucker rod string during downward travel.

Sinker Bars

Sinker bars provide concentrated weight above the pump to help keep the rod string straight and in tension, which reduces buckling of the sucker rods or the pump plunger. Norris sinker bars are made from hot rolled carbon manganese steel bar stock. Sinker bars are surface turned and have API double sucker rod pins, shoulders, and wrench flats on both ends. One end has a reduced section for elevator seating and lifting.

The current edition of API Specification 11B recognizes two grades of sinker bars:

API Grade 1 - Carbon (AISI 10XX) and

API Grade 2 - Alloy (Optional with manufacturer)

Below are the material types offerd by Norris relative to the two recognized API grades.

API Grade Material Type Mechanical Strength Properties

1. AISI 1024 Plain Carbon Steel 65,000 psi minimum tensile

2. AISI 4623 Nickel-Molybdenum Alloy Steel 90,000 psi minimum tensile.

In general terms API Grade 1 is referred to as Grade C while API Grade 2 is referred to as Grade K depending on material alloy type.

Ordinary sizes and mechanical properties of steel sinker bar:

|

External diameter |

external thread |

Wrench square |

Wrench square |

Sinker bar |

Mechanical |

|---|---|---|---|---|---|

|

1 1/4(31.75) |

5/8(15.9)SR |

25.4 |

31.8 |

7600;9100 |

1. Class-1:

2. Class-2: |

|

1 1/4(31.75) |

3/4(19.1)PR |

25.4 |

31.8 |

7600;9100 |

|

|

1 3/8(34.93) |

5/8(15.9)SR |

25.4 |

31.8 |

7600;9100 |

|

|

1 3/8(34.93) |

3/4(19.1)PR |

25.4 |

31.8 |

7600;9100 |

|

|

1 1/2(38.1) |

3/4(19.1)SR |

33.3 |

38.1 |

7600;9100 |

|

|

1 5/8(41.28) |

7/8(22.2)SR |

33.3 |

38.1 |

7600;9100 |

|

|

1 3/4(44.45) |

7/8(22.2)SR |

38.1 |

41.3 |

7600;9100 |

Inquiry for Our Product

LANTYTO® Machine

E-mail:

landy.industry21@gmail.com

When you contact us, please provide your detail requirements.

That will help us give you a valid quotation.