Sucker Rod with Various Grades and Specs

Introduction

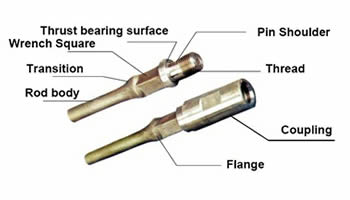

Sucker rod is the common equipment in the oil extraction. It is manufactured through many process including the testing, straightening and forging. The sucker rod is placed between the polished rod and oil well pump. To deliver power. Sucker rod is manufactured from high quality carbon steel and alloy steel, which is conform to the API Spec 11B standard. Sucker rod has various types including the common sucker rod, hollow sucker rod and FRP sucker rod. Commonly we use the sucker rod coupling to connect the sucker rod. The sucker rod also has various specs to fit different environments and applications.

Explanation of the sucker rod.

Classification

The sucker rod has various types:

- Common sucker rod

- Grade C sucker rod.

- Grade D sucker rod.

- Grade K sucker rod.

- Grade KD sucker rod.

- High tensile sucker rod: grade H sucker rod

- Grade HY sucker rod.

- Grade HL sucker rod.

- Grade KHL sucker rod.

- Special sucker rod: hollow sucker rod

- Continuous sucker rod.

- Screw pump sucker rod

- Taper thread sucker rod

- Plug sucker rod.

- FRP sucker rod: fiber reinforced plastic sucker rod

- Flexible sucker rod

- Carbon fiber composite sucker rod

- Steel wire rope sucker rod.

- Electric sucker rod

| Mechanical sheet of the different grade sucker rod | |||||

|---|---|---|---|---|---|

| Item | Grade | Tensile strength MPa | Yield strength MPa | Percentage elongation % | Contraction percentage of area % |

| ESRM-01 | C | 620 - 795 | ≥ 415 | ≥ 13 | ≥ 50 |

| ESRM-02 | K | 620 - 795 | ≥ 415 | ≥ 13 | ≥ 60 |

| ESRM-03 | D | 795 - 965 | ≥ 590 | ≥ 10 | ≥ 50 |

| ESRM-04 | KD | 795 - 965 | ≥ 590 | ≥ 10 | ≥ 50 |

| ESRM-05 | HL | 965 - 1195 | ≥ 795 | ≥ 10 | ≥ 45 |

| ESRM-06 | HY | 965 - 1195 | N/M | N/M | N/M |

Grade H sucker rod is the extra high tensile sucker rod.

Hollow sucker rod is a special structure of the sucker rod.

Specification

- Material: high quality carbon steel or alloy steel.

- Grade: C, D, K, H.

- Rod diameter: 5/8", 3/4", 7/8", 1" and 1-1/4".

- Length:

- 25', 26' and 30' for sucker rod.

- 2', 4', 6', 8', 10' for pony rod.

| Item | Size | Rod D. | Thread D. | Length | O.D. of pin shoulder | Length of pin | Wrench square size | |

|---|---|---|---|---|---|---|---|---|

| Length | width | |||||||

| ESRS-01 | 5/8" | 5/8" | 5/8" | 2' / 4' / 6' / 8' / 10' / 25' / 30' | 31.75mm | 31.75mm | ≥ 31.75mm | 22.23mm |

| ESRS-02 | 3/4" | 3/4" | 3/4" | 38.10mm | 36.51mm | ≥ 31.75mm | 25.40mm | |

| ESRS-03 | 7/8" | 7/8" | 7/8" | 41.28mm | 41.28mm | ≥ 31.75mm | 25.40mm | |

| ESRS-04 | 1" | 1" | 1" | 50.80mm | 47.63mm | ≥ 38.10mm | 33.34mm | |

| ESRS-05 | 1-1/8" | 1-1/8" | 1-1/8" | 57.15mm | 53.98mm | ≥ 41.28mm | 38.10mm | |

Production

- For common sucker rod:

Raw Material Test → Cold Straighten → Cut → Forge → Hot Treatment → Hot Alignment → Shot Blasting → Rod Head Machining → Assembly → Protective Cap → Package → Aczoiling Treatment. - For extra high tensile sucker rod:

Raw Material Test → Cold Straighten → Cut → Forge → Quenched And Tempered → Hot Treatment → Hot Alignment → Shot Blasting → Rod Head Machining → Surface Quenched → Assembly → Protective Cap → Package → Aczoiling Treatment.

Shot blasting.

Packing.

Package and loading

- Package:

- Metal pallet for saving space and convenient to transport.

- Plastic paper covering the sucker rod and metal box covering the rod head and then metal pallet for better corrosion and abrasion resistance.

- Pallet size (L × W× H):

- 7930mm × 550mm × 330mm

- 8300mm × 550mm × 330mm

- 9440mm × 550mm × 330mm

- Container size:

- 40' GP (40' general purpose container).

- 40' OT (40' open top container).

| Item | Dimension | Length Ft. | Pieces/ bundle | Net weight KG | Gross weight KG | Total pieces |

|---|---|---|---|---|---|---|

| ESRP-01 | 5/8" | 25' | 150 | 1930 | 1938 | 1920 |

| ESRP-02 | 26' | 150 | 1945 | 1953 | 1920 | |

| ESRP-03 | 30' | 150 | 2210 | 2218 | 1690 | |

| ESRP-04 | 3/4" | 25' | 100 | 1850 | 1858 | 1345 |

| ESRP-05 | 26' | 100 | 1865 | 1873 | 1334 | |

| ESRP-06 | 30' | 100 | 2120 | 2128 | 1174 | |

| ESRP-07 | 7/8" | 25' | 80 | 1920 | 1925 | 1039 |

| ESRP-08 | 26' | 80 | 2012 | 2017 | 991 | |

| ESRP-09 | 30' | 80 | 2290 | 2290 | 897 | |

| ESRP-10 | 1" | 25' | 60 | 1915 | 1923 | 780 |

| ESRP-11 | 26' | 60 | 2006 | 2014 | 744 | |

| ESRP-12 | 30' | 60 | 2278 | 2283 | 657 | |

| ESRP-13 | 1-1/8" | 25' | 50 | 2044 | 2052 | 609 |

| ESRP-14 | 26' | 50 | 2135 | 2143 | 583 | |

| ESRP-15 | 30' | 50 | 2392 | 2398 | 521f |

| Item | Dimension | Length Ft. | Pieces/ bundle | Net weight KG | Gross weight KG | Total pieces |

|---|---|---|---|---|---|---|

| ESRP-01 | 5/8" | 25' | 150 | 1930 | 1938 | 1920 |

| ESRP-02 | 26' | 150 | 1945 | 1953 | 1920 | |

| ESRP-03 | 30' | 150 | 2210 | 2218 | 1690 | |

| ESRP-04 | 3/4" | 25' | 100 | 1850 | 1858 | 1345 |

| ESRP-05 | 26' | 100 | 1865 | 1873 | 1334 | |

| ESRP-06 | 30' | 100 | 2120 | 2128 | 1174 | |

| ESRP-07 | 7/8" | 25' | 80 | 1920 | 1925 | 1039 |

| ESRP-08 | 26' | 80 | 2012 | 2017 | 991 | |

| ESRP-09 | 30' | 80 | 2290 | 2290 | 897 | |

| ESRP-10 | 1" | 25' | 60 | 1915 | 1923 | 780 |

| ESRP-11 | 26' | 60 | 2006 | 2014 | 744 | |

| ESRP-12 | 30' | 60 | 2278 | 2283 | 657 | |

| ESRP-13 | 1-1/8" | 25' | 50 | 2044 | 2052 | 609 |

| ESRP-14 | 26' | 50 | 2135 | 2143 | 583 | |

| ESRP-15 | 30' | 50 | 2392 | 2398 | 521 |

Sucker rods are packaged by the metal pallet.

Sucker rod in plastic paper, metal box, angle steel and bolts package.

Features

- Various grade to fit different requirements.

- Various types to satisfy different environments.

- Angle steel and bolts package for convenient transport and saving space.

- Plastic or metal sucker rod protectors to protect the threads.

- Plastic paper and metal box to resist the corrosion and abrasion.

- Special specifications can be customized.

Plastic cap can protect the thread.

Angle steel and bolts package for saving space and convenient transport.

Applications

The sucker rod is widely used in the oil extraction industries. The different grade sucker rod can be applied in different applications.

- Grade C sucker rod: Moderate strength, has a certain degree of resistance to the sulfide stress cracking, it is suitable for sour environments.

- Grade D sucker rod: The grade D sucker rod is manufactured from high quality heat treated steel alloy, which has high tensile and yield strength, it is can be used in the non-corroding or mildly corroding environments.

- Grade K sucker rod: The grade K sucker rod has a good corrosion resistance in H2S, CO2, and NaCl media, it is widely used in corrosion environments.

- Grade H sucker rod: This is a type of sucker rod with extra high tensile strength it is ideal for deep and large wells.

Inquiry for Our Product

LANTYTO® Machine

E-mail:

landy.industry21@gmail.com

When you contact us, please provide your detail requirements.

That will help us give you a valid quotation.